from-a-box-to-a-patient-treatment-place-developments-in-our-makerspace-feature-CADUS20Maker20Space20Nov202020-7-ef3cb9ac

From box to a patient treatment place – developments in our makerspace

The requirements for equipment used in crisis areas are often quite different from those for normal medical equipment. In our Makerspace, we are currently developing various projects needed for missions. Two of our latest builds are a mobile washbasin and a modular treatment stations for patients.

When we are not on a mission abroad, we are busy working on projects with volunteer supporters in our Crisis Response Makerspace (CRM). During missions, we often encounter unforeseen problems, for which we then find a solution in the workshop. Last spring, the Makerspace briefly became a logistics center for Faceshields when we participated in an initiative of open workshops. In the meantime, however, all the face shields have left the Makerspace again and there is plenty of room to work.

Requirements for humanitarian work

Humanitarian work in crisis and war zones often comes with special requirements that have to be taken into account when designing and developing equipment. After natural disasters, such as an earthquake, the existing infrastructure is often destroyed and no longer usable. That’s why all solutions developed in CRM must be able to function independently. They either have to manage without electricity or need their own power supply; the same applies to water or gas. Not relying on local infrastructure is challenging, but one of the most important principles for development.

Mobile Washbasin

This self-sufficient design is particularly obvious in the mobile washbasin, one of our current projects. Access to clean water is not always available during our missions, but washing hands is essential for medical work, not only in times of pandemic. That is why we have developed a washbasin that is adapted to all eventualities in missions.

This self-sufficient design is particularly obvious in the mobile washbasin, one of our current projects. Access to clean water is not always available during our missions, but washing hands is essential for medical work, not only in times of pandemic. That is why we have developed a washbasin that is adapted to all eventualities in missions.

If a functioning water network is available, the washbasin can simply be connected to it. Otherwise, it is equipped with a 40-liter tank and an electric pump that generate running water. If no electricity is availabe, we make use of something that is always there: Gravity. The height of the tank creates enough water pressure for easy hand washing.

The mobile washbasin consists of three parts: a tank (top), the actual washbasin (middle) and the canisters for the wastewater (bottom). Photo: (c) Till Rimmele

For missions in cold areas, there is the option to connect an instantaneous water heater or a boiler. The whole sink can be compactly packed for transport to the size of a travel suitcase.

The sink packed together. Photo: (c) Till Rimmele

The sink packed together. Photo: (c) Till Rimmele

This mobility is a second important requirement in humanitarian aid. In areas where long-term planning is often not possible, easily movable equipment is needed. In the event of a sudden flood, for example, there is rarely time to move equipment to a specific location by ship for weeks. Projects like a mobile hospital can often help more people if it is able to quickly change its position and move to hot spots.

Patient Treatment Places

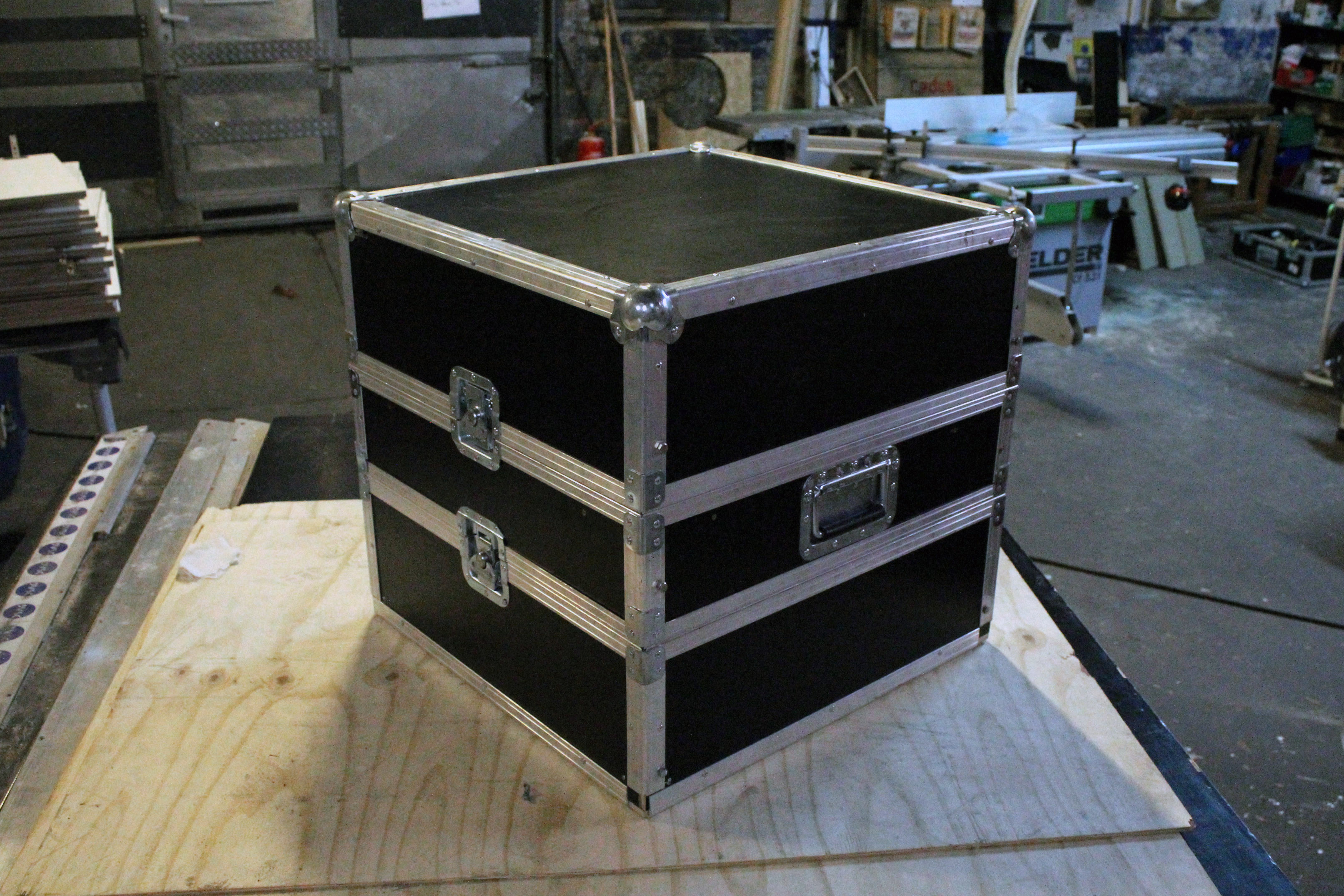

An integral part of such a mobile hospital are the treatment stations: Like almost everything in a mobile hospital, these treatment stations must be integrated into a transport box system. Since resources and space on site are limited, they must be quick and self-explanatory to set up and dismantle.

The Patient Treatment Place can be assembled in just a few simple steps. Photo: (c) Till Rimmele

The Patient Treatment Place can be assembled in just a few simple steps. Photo: (c) Till Rimmele

The material has to meet certain requirements as well: it must not only be easy and hygienic to clean, but it should also be tough and available in crisis areas. The treatment places that we have developed in the Makerspace are made of a stable plywood material with a melamine resin coating. This material meets all the necessary requirements and is not only weather resistant, waterproof and easy to clean, but also scratch resistant and flame retardant. The wood was processed into an extendable box and a foldable lounger. In addition, there is a special snap-in system developed by us to securely connect the box and lounger together.

A prototype of the patient treatment places. Photo: (c) Till Rimmele

A prototype of the patient treatment places. Photo: (c) Till Rimmele

You’re in Berlin, like to tinker yourself and feel like being in the workshop again? We are currently looking for support to build new projects, for example we are planning a mobile and modular emergency ambulance for war and crisis areas. We would be happy if you write us! Especially we are looking for people with these skills:

- CNC and CAD: Create technical drawings and milling files

- Wood and metal working

- Product Design/ Industrial Design, User Experience

- Documentation of open source projects

If you found yourself in this list, or would like to support us in any other way, feel free to send us an eMail to makerspace@cadus.org.

Published

Author: by Cadus PR

By CadusPR

Stay informed about our missions, events and humanitarian emergency aid topics – with our newsletter!

Newsletter registration

I want to unsubscribe from the newsletter.